TECHNOLOGIES

HOW WE WORK

FI.DAL. Stampi focuses on the continuous updating of our machinery to guarantee precision, quality and speedy delivery of moulds to customers. Over the years we have studied the evolution of our industry, keeping up with the most innovative equipment and investing in the growth of our team. In fact, in addition to high-level technologies, the key factors of our success are the skill, attention and experience of our employees.

Machining centres

We have 6 machining centres at our disposal. These numerically controlled machine tools allow us to perform most of the machining operations to obtain the moulds required by our customers.

Our state-of-the-art machinery allows excellent manufacturing capacity, high reliability and absolute precision in the final result.

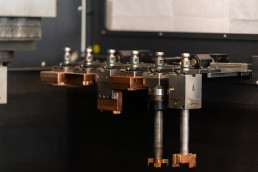

Plunge EDM

Our company is equipped with 4 sinker EDMs (2 of which are CNC-controlled).

The material removal process takes place thanks to the formation of electrical discharges between the electrode and the mould being machined, all within a liquid dielectric.

The strength of this technology is the possibility of realising cuts, sharp edges, ribs and cavities that are impossible with conventional techniques, thus achieving a high level of detail and guaranteeing the achievement of geometrically complex mathematics. We also use this machinery to perform finishes that improve the aesthetics of the plastic part according to the quality required by our customers.

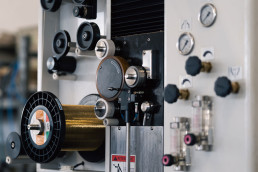

Wire EDM

In this technology, a 0.25 mm brass wire is used, which releases electrical discharges in order to machine the mould according to the guidelines defined in the design.

This machinery allows us to obtain flawless through profiles on any type of metal.

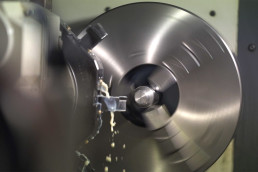

CNC lathe

The CNC lathe represents the ultimate evolution of the traditional lathe, improving performance when machining round components. Our machines are equipped with innovative technology that allows us to produce very high precision products, while also guaranteeing significant time savings in the construction of moulded parts.

Grinding machine

Within a mould, certain components require maximum accuracy and an extremely smooth surface. Our grinding machine is essential to achieve this type of treatment.

EDM micro-drilling machine

The EDM micro-drilling machine we have is a technology that uses the EDM process with a rotating perforated tube that allows us to create calibrated holes in any type of metal (from a minimum diameter of 0.5mm to a maximum of 6mm).

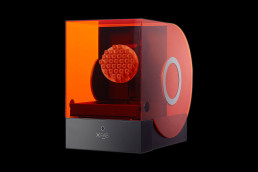

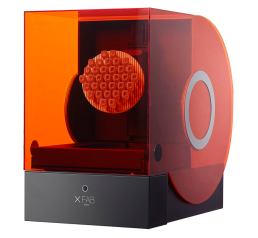

3D printer

This innovative technology builds the part using the principle of material addition from CAD software, as opposed to traditional technologies that work by removal.

Using our 3D printer, we create prototypes to simulate the final product required by customers, discuss its characteristics and facilitate our subsequent design of the relevant mould.