FI.DAL. STAMPI

Design and construction of plastic and die-casting moulds since 1994

FI.DAL. STAMPI

Design and construction of plastic and die-casting moulds since 1994

FI.DAL. Stampi owes its success to its founders:

Paolo Filippozzi and Bruno Dall’Osto.

First colleagues and then, united by the same desire and determination to strike out on their own, creators of the company FI.DAL. Stampi.

FI.DAL. Stampi was thus founded in 1994 and deals with the design and construction of injection moulds for plastics and die-casting, with the idea of offering quality and precision products to customers and the aim of establishing itself on the market through its own business values.

During the following years, continuous growth and renewal, hand in hand with new technologies, favoured the evolution of the company, which also specialised in the design and construction of unscrewing moulds and highly complex mathematics.

Over time, the company has invested in new state-of-the-art machinery and in the recruitment and training of qualified and highly specialised employees. These measures have enabled FI.DAL. Stampi to increase its production capacity and the quality of its products, producing increasingly precise and accurate moulds. In fact, the company boasts a technical department with highly experienced figures, a winning element to guarantee the design of a product in line with customer requirements.

Growth and innovation

Customised moulds

The result is highly customised moulds, which allow the creation of plastics that can be used in any production sector.

Business Values

FI.DAL Stampi believes strongly in customer relations. Transparency, adherence to agreements and customer service up to mould optimisation are the core values of their business.

About us

29 years

of experience in the

of moulds

Currently, FI.DAL. Stampi presents itself as a solid company specialising in the production of moulds for plastics and die-casting, representing the sector’s excellence in mould precision and on-time delivery of products within the deadlines agreed with customers.

Why choose us

Maximum precision moulds

Meeting deadlines

Support up to mould optimisation

Timely assistance

Modifications and repairs on moulds made by third parties

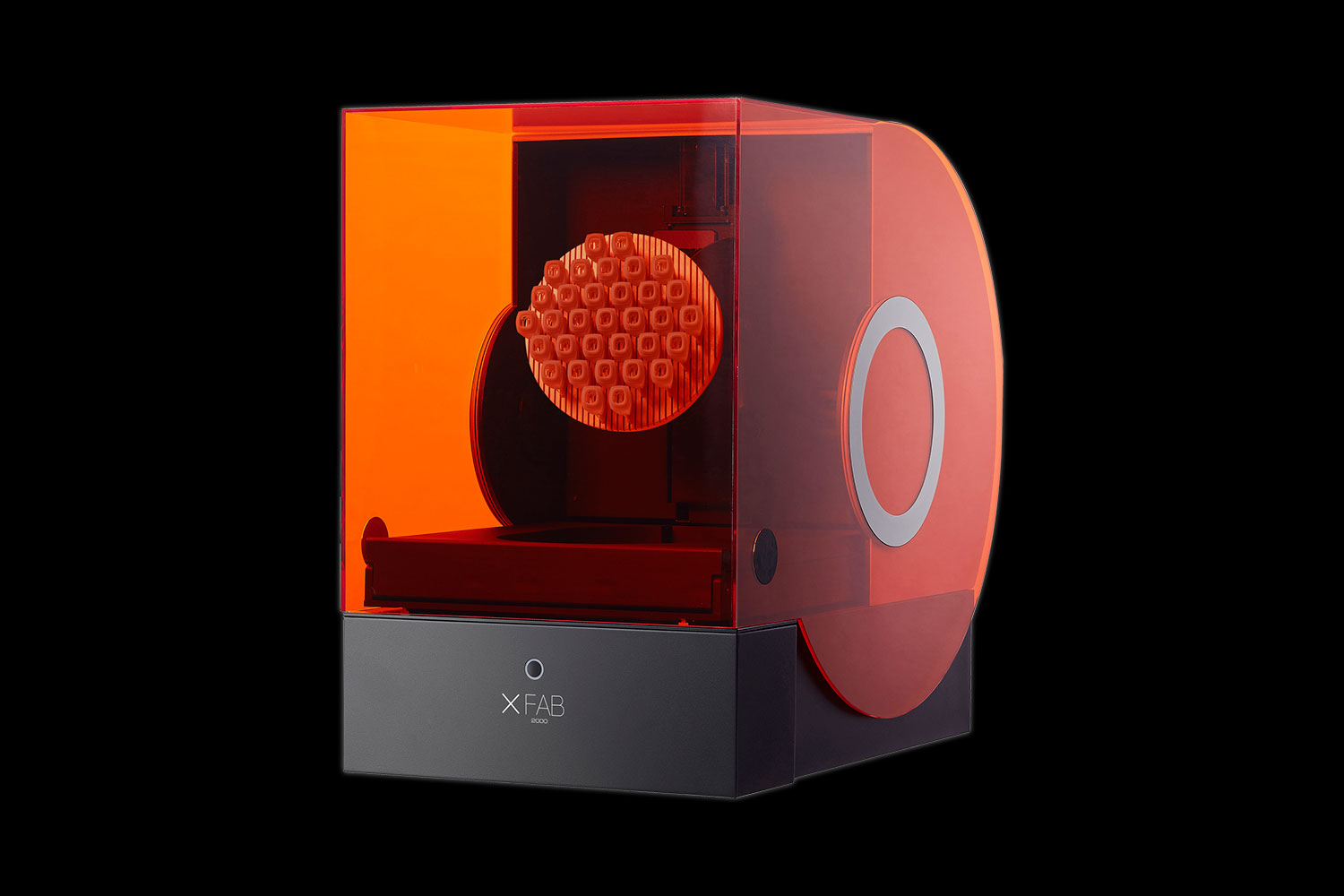

Prototype creation through 3D printer

3270

NUMBER OF MOULDS

999+

AREAS OF APPLICATION

153

SATISFIED CUSTOMERS

13

COLLABORATORS

It all starts here, in 1994

1994

FI.DAL. STAMPI FOUNDATION

1995

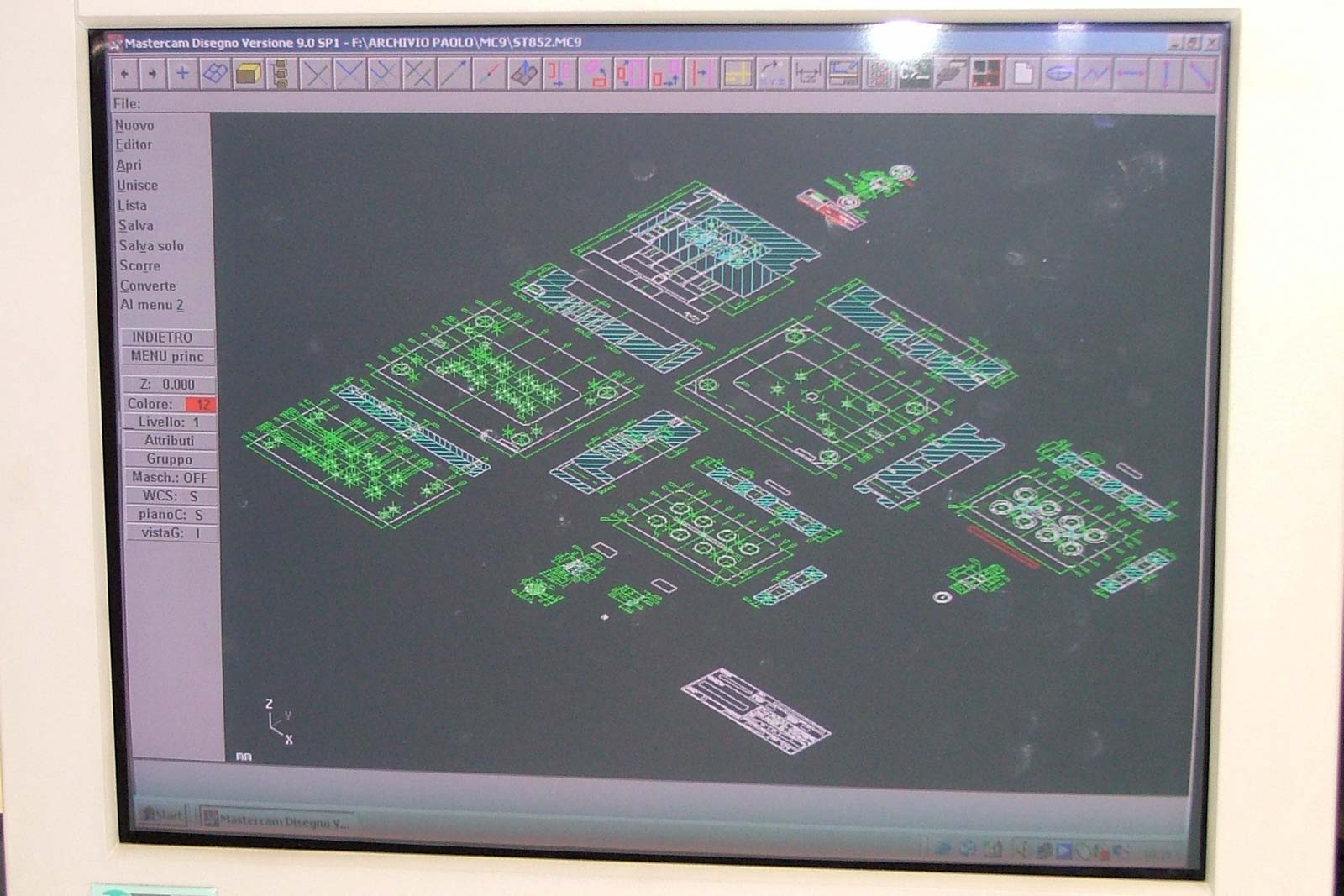

CAD - CAM

1997

MACHINING CENTRE

1998

DIE-SINKING EDM

2000

NEW FI.DAL. STAMPI

2003

THIRD WORK CENTRE

2010

CNC LATHE

2014

INCREASING MACHINE PARK

2016

3D PRINTER

2017

SECOND DIE-SINKING EDM

2018

RENEWAL OF MACHINING CENTRES

2020

PHOTOVOLTAIC PANELS

2022

INDUSTRY 4.0 MACHINING CENTRE

2023

SOCIAL MEDIA

1994

FI.DAL. STAMPI FOUNDATION

Foundation FI.DAL. Stampi by Filippozzi Paolo and Dall'Osto Bruno based in Montebello Vicentino in a 400 square metre plant

1995

CAD - CAM

Introduction of CAD systems for design and manufacture by numerically controlled machines

1997

MACHINING CENTRE

Purchase of the first CNC MACHINING CENTRE

1998

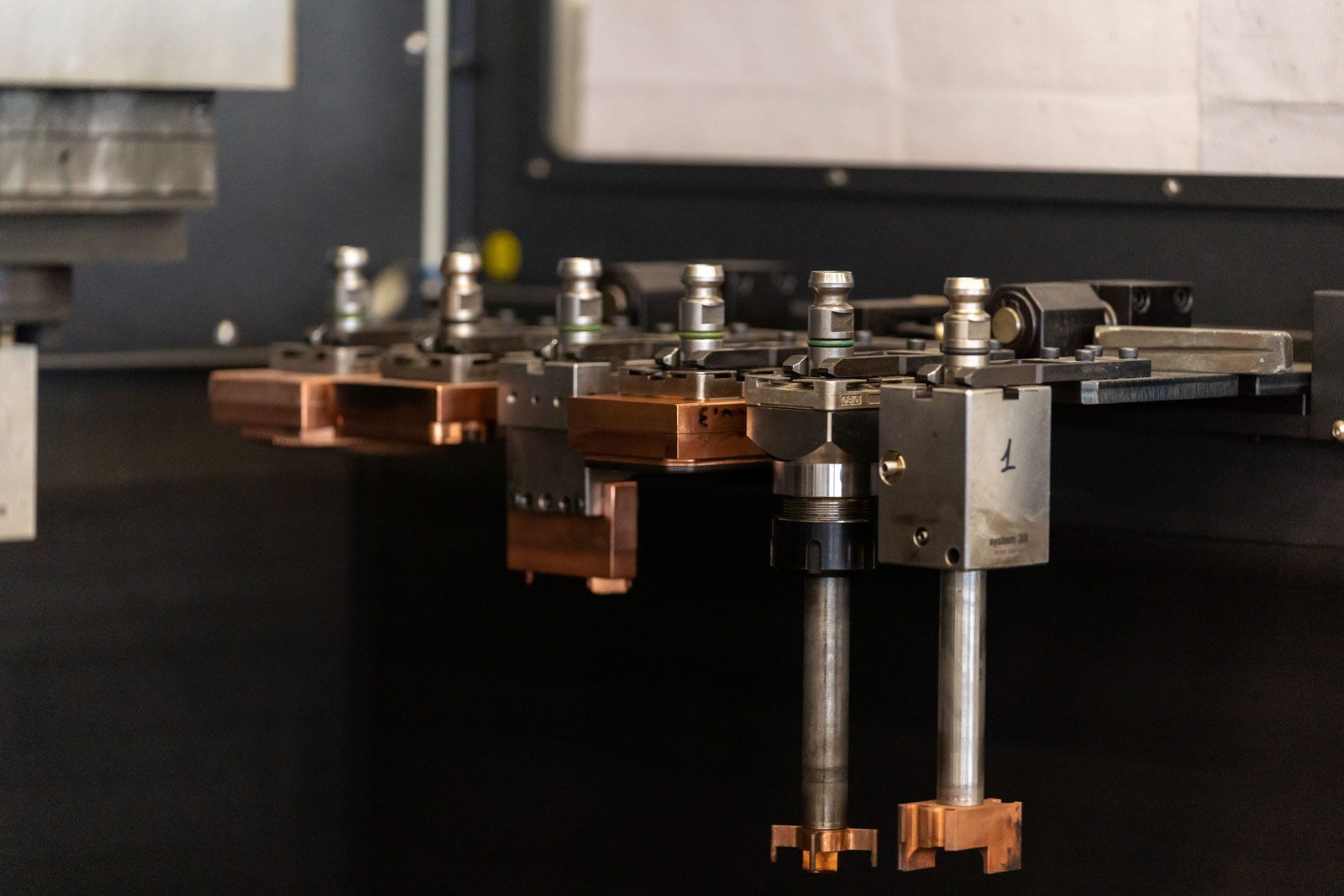

DIE-SINKING EDM

Purchase of the first CNC DIE ELECTROEROSION

2000

NEW FI.DAL. STAMPI

Relocation of company headquarters to a new factory of over 1000 square metres located in Gambellara

2003

THIRD WORK CENTRE

Increased production capacity through the purchase of the third CNC MACHINING CENTRE

2010

CNC LATHE

Purchase of a CNC lathe

2014

INCREASING MACHINE PARK

Expansion of the machine park with the purchase of a WIRED ELECTROEROSION and a MICRO-PERFORATING MACHINE

2016

3D PRINTER

Purchase of a 3D printer for prototyping

2017

SECOND DIE-SINKING EDM

Purchase of the second CNC DIE ELECTROEROSION

2018

RENEWAL OF MACHINING CENTRES

Replacement of CNC MACHINING CENTRES with new innovative and modern versions

2020

PHOTOVOLTAIC PANELS

Installation of photovoltaic panels at the plant

2022

INDUSTRY 4.0 MACHINING CENTRE

Purchase of sixth Industry 4.0 CNC Machining Centre

2023

SOCIAL MEDIA

Corporate website, social and logo restyling